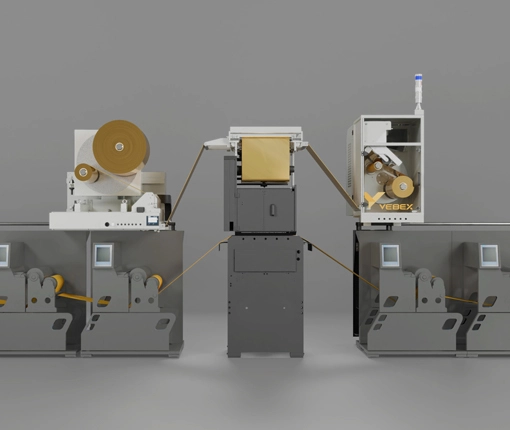

UNWINDER VBS-U

The VBS-U Unwinder is designed for continuous reel unwinding thanks to its integrated, patented automatic splicing unit, and allow to enhance the productivity of your printing lines.

OVERALL DIMENSIONS:

L: 2660 mm x W: 1700 mm x H: 2550 mm

WORKABLE PRODUCTS:

Type: paper, film ,sleeve and others

Diameter: up to 1000 mm

Width: from 440 mm to 670 mm

Core: 3” and 6”

PERFORMANCE:

Vmax: up to 250 m/min

Automatic edge alignment +/- 1 mm

Tension control +/- 1N

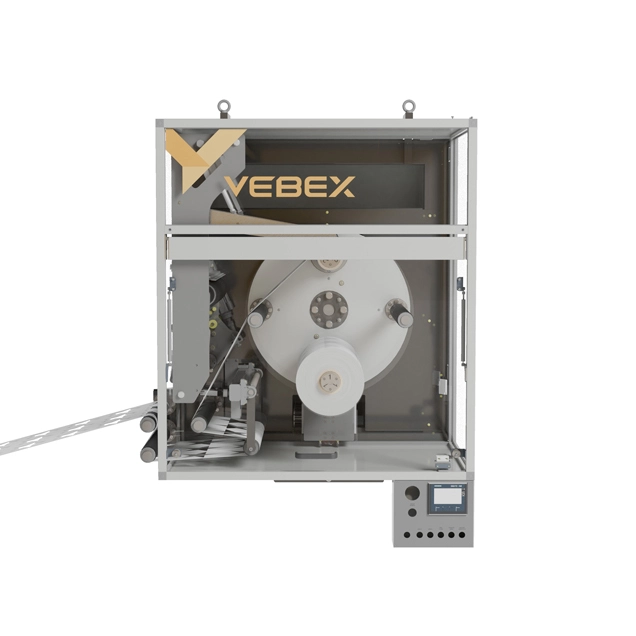

UNWINDER VBS-UE

The VBS-UE Unwinder is designed for continuous reel unwinding. It is a versatile version of the VBS-U Unit and has been designed for limited space layout and fast and simple production of paper, film, and multi-layer materials

OVERALL DIMENSIONS:

L: 1750 mm x W: 1500 mm x H: 3900 mm

WORKABLE PRODUCTS:

Type: paper, film, sleeve and others

Diameter: up to 1000 mm

Width: from 440 mm to 670 mm

Core: 3” and 6”

PERFORMANCE:

Vmax: up to 150 m/min

Vmax splice: up to 150m/min

MATRIX VBM

The VBM Rewinder Unit is designed for continuous rewinding Matrix waste, avoid line stop during the matrix reel change . The Unit that can placed onto the rail of any printing press and allow to enhance the productivity of your lines

OVERALL DIMENSIONS:

L: 1200 mm x W: 1000 mm x H: 1270 mm

WORKABLE PRODUCTS:

Type: Matrix waste of glossy paper, natural

paper, wax paper, PP, Pet and others

Diameter: up to 400 mm

Width: from 440 mm to 670 mm

PERFORMANCE:

Vmax: up to 150 m/min

Vmax splice: up to 150m/min

Tension control sytem

TURRET REWINDER VBS-RE

The Turret Rewinder is designed for continuous reel rewinding. It boosts production efficiency by finishing rolls of saleable products directly in line, eliminating the finishing table process. The system can be configured with a wide range of options: slitting, gluing system, auto core positioning and extraction, banana roll and many others

OVERALL DIMENSIONS:

L: 1300 mm x W: 1500 mm x H: 2100 mm

WORKABLE PRODUCTS:

-Manual or auto slitting

-Gluing system

-Auto core positioning ande xtraction

-Bowl feeder

-Banana rooll

-and many others

PERFORMANCE:

Vmax: up to 150 m/min

Vmax splice: up to 150m/min

Diameter: from 50 mm to 800 mm

REWINDER VBS-R

The VBS-R Rewinder is designed for continuous reel rewinding significantly increasing the productivity of your printing and converting lines. With dedicated software is able to process a wide range of substrates, including paper, film, sleeve, aluminum, slippery and complex materials.

OVERALL DIMENSIONS:

L: 1300 mm x W: 2100 mm x H: 2200 mm

WORKABLE PRODUCTS:

Type: paper, film, sleeve and others

Diameter: up to 800 mm

Width: from 440 mm to 670 mm

Core: 3" and 6"

PERFORMANCE:

Vmax: up to 250 m/min

Vmax splice: up to 250 m/min

Winding by meter or diameter

UNWINDER VBF-U

UNWINDER VBF-R

The No Stop Rewinder and Unwinder VBF Units for Foil are dedicated to enhance the productivity of Cold and Hot Foil embellishment station. The Unit concentrates years of research and development in processing complex thin materials that requires special tension control system at high speed.

OVERALL DIMENSIONS:

L: 1000 mm x W: 1100 mm x H: 1200 mm

WORKABLE PRODUCTS:

Type: paper, film and others

Diameter: up to 600 mm

Width: from 440 mm to 670 mm

Core: 3” and 6”

PERFORMANCE:

Vmax: up to 150 m/min

Vmax splice: up to 150m/min

Tension control system

TABLE TOP REWINDER

It is an offline machinery dedicated to restore single lane reels, troubleshoot issue and replace single label. The Table Top VBT as per all the VEBEX products is equipped with high technological components and dedicated tension control software.

OVERALL DIMENSIONS:

L: 1300 mm x W: 700 mm x H: 1200 mm

WORKABLE PRODUCTS:

Type: paper, film, sleeve and others

Diameter: up to 400 mm

Width: up to 250 mm

Core: 3" and 6"

PERFORMANCE:

Vmax: up to 250 m/min